In the fast-paced world of manufacturing, High Volume Machining stands as a cornerstone for meeting increasing demands and maintaining competitive edges. Efficiency in this realm is not just a goal; it’s a necessity. As technology evolves, so do the strategies for optimizing high volume machining processes. In this comprehensive guide, we delve into the top tips that can elevate your machining efficiency, ensuring not only productivity but also precision.

Invest in Advanced Machining Tools

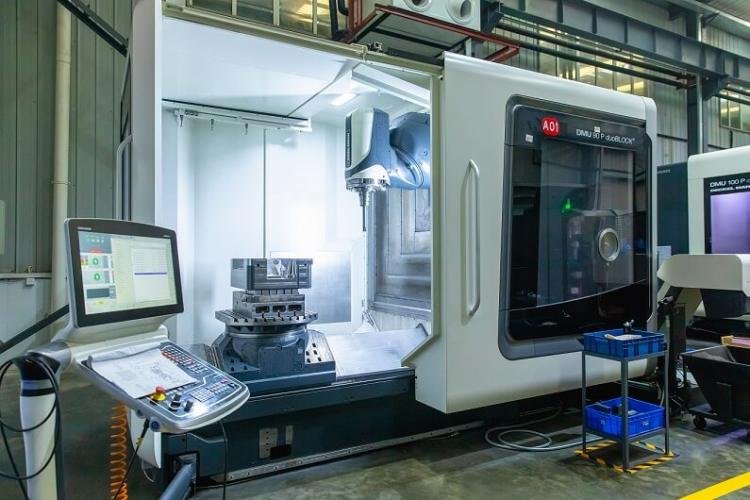

The backbone of high volume machining lies in the tools used. Investing in state-of-the-art machining tools can significantly enhance efficiency. High-speed machining centers, precision cutting tools, and advanced tool coatings contribute to faster and more accurate production processes. This section explores the latest innovations in machining tools and their impact on efficiency.

Implement Lean Manufacturing Principles

Lean manufacturing principles are indispensable for optimizing high volume machining efficiency. By eliminating waste, reducing downtime, and streamlining processes, manufacturers can achieve higher output without compromising quality. This section provides practical insights into implementing lean principles, including value stream mapping, 5S methodology, and continuous improvement strategies.

Utilize Automation and Robotics

The integration of automation and robotics has revolutionized high volume machining. From CNC machining to material handling, automation enhances efficiency by minimizing human intervention, reducing errors, and maximizing uptime. This section explores the various applications of automation and robotics in high volume machining and offers guidance on implementing these technologies effectively.

Optimize Toolpath Strategies

Efficient toolpaths are crucial for achieving optimal results in high volume machining. By utilizing advanced CAM (Computer-Aided Manufacturing) software and optimizing toolpath strategies, manufacturers can reduce cycle times and enhance tool life. This section discusses the importance of toolpath optimization and provides tips for maximizing machining efficiency through intelligent programming.

Monitor and Analyze Data

In the era of Industry 4.0, data is a powerful ally in optimizing high volume machining processes. By implementing sensors and analytics tools, manufacturers can monitor machine performance, identify bottlenecks, and make data-driven decisions for continuous improvement. This section explores the role of data in machining efficiency and offers insights into effective monitoring and analysis techniques.

Prioritize Preventive Maintenance

Unplanned downtime can be a significant hindrance to high volume machining efficiency. Prioritizing preventive maintenance helps in identifying and addressing potential issues before they escalate. This section outlines the importance of a robust maintenance schedule and provides tips for implementing preventive maintenance practices to ensure uninterrupted production.

Conclusion

In the ever-evolving landscape of high volume machining, efficiency is the key to staying ahead. By adopting advanced technologies, lean principles, and data-driven strategies, manufacturers can optimize their machining processes for higher volumes without compromising on precision and quality. Implementing these top tips not only ensures short-term gains but also establishes a foundation for sustained success in the dynamic world of high volume machining.