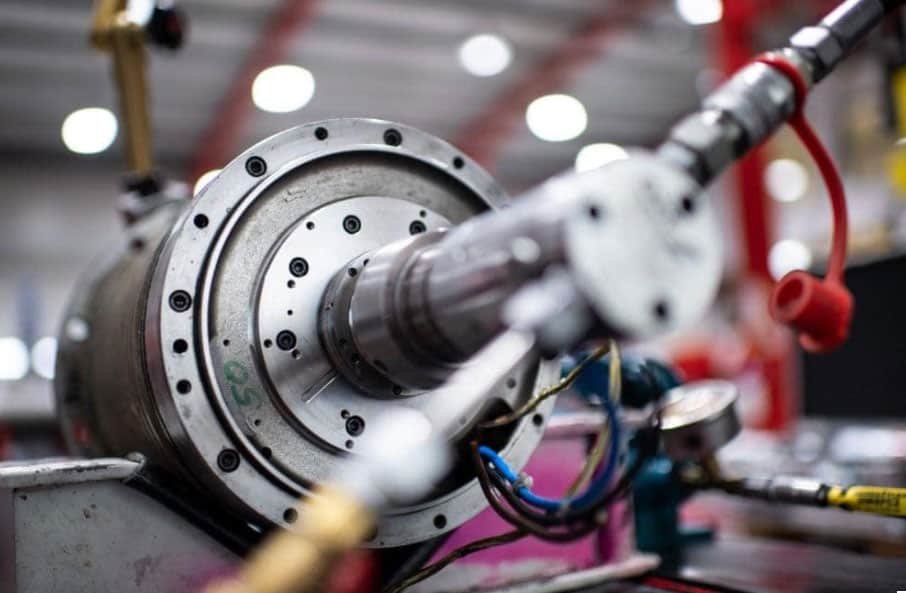

CNC (Computer Numerical Control) machines are an essential part of many industries, from manufacturing to healthcare. These machines are relied upon to perform precise and accurate tasks with high efficiency. However, like any machine, CNC machines are susceptible to wear and tear and require regular maintenance and repair to function optimally. CNC machine repair services are necessary to keep these machines in good condition, and it’s crucial to minimize repair costs to keep business operations running smoothly. In this blog post, we will discuss how to minimize CNC machine repair costs in Erie and recommend using Exact Machine Service Inc., a leading CNC machine repair service in Erie.

Regular Maintenance

Regular maintenance is essential to minimize CNC machine repair costs. CNC machines are complex machines that require proper maintenance to ensure they function optimally. Proper maintenance helps to identify potential problems early on and prevent them from escalating into more significant issues. Regular maintenance also helps to prolong the lifespan of the machine, preventing costly repairs in the long run.

Proper Training

Proper training is crucial to minimize CNC machine repair costs. It’s essential to ensure that the machine operators are adequately trained in operating the machine to prevent operator error, which can lead to costly repairs. The machine operators should also be trained in identifying potential problems and reporting them promptly to the maintenance team to avoid costly repairs.

Qualified Technicians

Qualified technicians are essential to minimize CNC machine repair costs. Skilled technicians with experience in handling a wide range of CNC machines can quickly diagnose and repair issues, preventing them from escalating into more significant problems. Qualified technicians can also recommend upgrades to the machine to prevent breakdowns and minimize repair costs in the long run.

Upgrades

Upgrades are necessary to minimize CNC machine repair costs. Upgrades such as adding new software, replacing worn-out parts, or installing new components can improve the machine’s efficiency and prevent costly repairs. Regular upgrades can also help to extend the machine’s lifespan and minimize the need for frequent repairs.

Use of OEM Parts

The use of OEM (Original Equipment Manufacturer) parts is essential to minimize CNC machine repair costs. OEM parts are manufactured to the same specifications as the original parts, ensuring that they fit and function correctly. The use of OEM parts ensures that the machine runs efficiently, minimizing the need for costly repairs. It’s essential to use a CNC machine repair service that uses OEM parts to ensure that the machine operates optimally.

Why Choose Exact Machine Service Inc.?

Exact Machine Service Inc. has been leading the field of CNC repair services in Erie for many years. The company has a team of skilled technicians with experience in handling a wide range of CNC machines. The technicians are trained to diagnose and repair issues quickly and efficiently, minimizing downtime and repair costs. The company also provides regular maintenance services to prevent potential problems, prolonging the lifespan of the machine and minimizing repair costs. Exact Machine Service Inc. uses OEM parts in all repairs and upgrades, ensuring that the machines operate efficiently and minimizing the need for frequent repairs.

CNC machines are essential in many industries, and regular maintenance and repairs are necessary to keep them functioning optimally. Minimizing CNC machine repair costs requires regular maintenance, proper training, qualified technicians, upgrades, and the use of OEM parts. Choosing a reputable CNC machine repair service like Exact Machine Service Inc. can help minimize repair costs and prevent costly breakdowns. Exact Machine Service Inc. provides top-notch CNC machine repair services in Erie, and their team of skilled technicians can diagnose and repair issues quickly and efficiently, minimizing downtime and repair costs.