1. Introduce

With the rapid development of industrial robot technology, the market for used robots and robot parts is gradually emerging. Buying used robots and robot parts becomes an attractive option for businesses looking for cost-effective and sustainable solutions. However, when choosing quality used robots and robot parts, there are some key steps to take to ensure performance, reliability and adaptability. We will discuss how to choose good used robots and parts from the original application of the robot.

2. Learning about the original application environment of the robot

It takes careful deliberation of various factors to decide upon a good robot. To make an informed decision these factors should be kept in mind. The following are a few of the factors that are significant when making this decision.

· Understanding the original application:

One needs to identify the original purpose and application of the industrial robot that is up for consideration. They need to understand the tasks it was designed to perform and gain information about any specific requirements related to its original application.

· Evaluate environmental conditions:

One must consider any and all environmental conditions that the robot was originally used in. Many of these factors can affect the condition of the robot and its performance. Temperature, dust levels, humidity, and even exposure to chemicals can highly affect the performance of the robot. Therefore, it is highly important to check the environmental conditions.

· Assess wear and tear

Physical inspection of the robot is also important as some parts of the robot might need to be replaced immediately. One needs to pay attention to its movements, sensors, and any specialized functions for any dysfunction. If there are any signs of excessive wear, it may indicate a dire need for replacement parts.

· Check for modifications and upgrades

One needs to determine if the robot has undergone any upgrades or modifications. This may also determine if the robot’s capabilities have been affected. Features such as updated software, hardware, and any additional features might affect its performance. Hence, it is important to inspect the robot’s components.

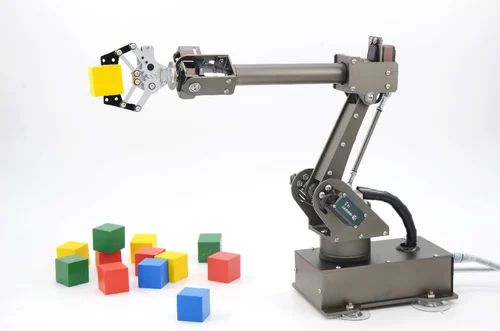

Alt: FANUC Robot

Select accessories based on the original robot’s tasks

- When choosing grippers or end-effectors, choose ones tailored to the robot’s tasks. Furthermore, ensure that these accessories are compatible with the specific model and version of the robot. Inspection of the accessories and confirmation of compatibility also plays a significant role in its selection.

- Upgraded versions or additional features that can be integrated into the accessories also play a vital role in its selection. The upgraded versions may prove to be more beneficial and more efficient than the previous ones.

- Obtaining the maintenance and service records for the accessories may be important as they can show the true reliability and efficiency of the robot. If possible, the customer should check the compatibility of the robot and robot parts, this can identify any potential risks and problems before purchasing it.

Consider the robot’s range of motion and degrees of freedom

The range of motion is the extent to which a robot’s end effector can move in different directions. The degree of freedom refers to the number of parameters or movements a robot can make. Both of these are important as they can increase the flexibility and ability to perform precise tasks, it also enhance the robot’s versatility. Robots that provide a wide range of motion are beneficial for the assembly of components and enable them to pick and place robots from various locations within its reach. Robots in surgical procedures require high degrees of freedom for precise movements and industrial robots used in welding or painting benefit from various degrees of freedom to access various angles and orientations.

Consider robot control systems

Focusing on the compatibility, reliability, and adaptability of the control system plays a huge factor in choosing second hand robots and accessories. The following are some of the points to keep in mind when making this informed decision.

· Verification of safety features

Adequate safety features such as collision detection, stop capabilities, and other safety protocols are highly important in this day and age. If the robot is to be used in a safety critical environment, these features are of immense need.

· Assess user interface

A thorough evaluation of the user interface is important as it may be too difficult for some users to handle. Hence, an intuitive interface can simplify the programming and operation of the robot, making it easy to use. The interface should also meet the needs and demands of the users operators and programmers.

· Evaluate controller hardware

Physical inspection of the controller’s hardware can have an impact on its performance. If any signs of wear and tear are visible, it may be wise to replace such components. However, critical components such as the CPU, memory, input/ output modules should be in perfect condition for proper functioning of the robot.

· Test control system functionality

Ensuring that the test control system can properly communicate with the robot’s components, sensors and its accessories is of utmost importance. Therefore, if possible, the customer should check that the control system communicates properly with the components.

· Check manufacturer support

The user should verify if the manufacturer provides support for the control system as it can be very beneficial to the user. Access to documentation, software updates and even technical support may be valuable to the user. It may be used for troubleshooting and maintenance.

· Consultation with experts

If the user has access to any experts who are familiar with the specifications of the control systems or brand, they can provide useful insights into the systems strengths, weaknesses and sustainability.

Therefore, by carefully evaluating the control systems along with the original application and accessories, users should make a definite decision while purchasing second hand robots.

Conclusion

Choosing used robots and accessories requires a thorough understanding of their original application. Analyzing the tasks that the robot was originally designed for is paramount. Furthermore, one should evaluate whether those tasks align with the intended purpose in the new context. The compatibility and overall condition of the robot and its accessories should also be kept in mind. Request detailed maintenance records and service history to assess the remaining operational lifespan.

By careful consideration of these factors, individuals can make informed decisions when selecting used robots and accessories. This approach not only maximizes the potential of the repurposed robotic systems but also contributes to the efficient and cost-effective implementation of automation technologies.