In the realm of modern manufacturing, various techniques and technologies have revolutionized the way intricate parts are produced. One such method is Sinker EDM Machining, which stands for Electrical Discharge Machining. Sinker EDM is widely used in industries that require high precision and complex geometries. In this article, we will delve into the basics of Sinker EDM Machining, explore its common uses, and recommend the services of Iron Machine Tool for all your Sinker EDM Machining needs.

Understanding Sinker EDM Machining

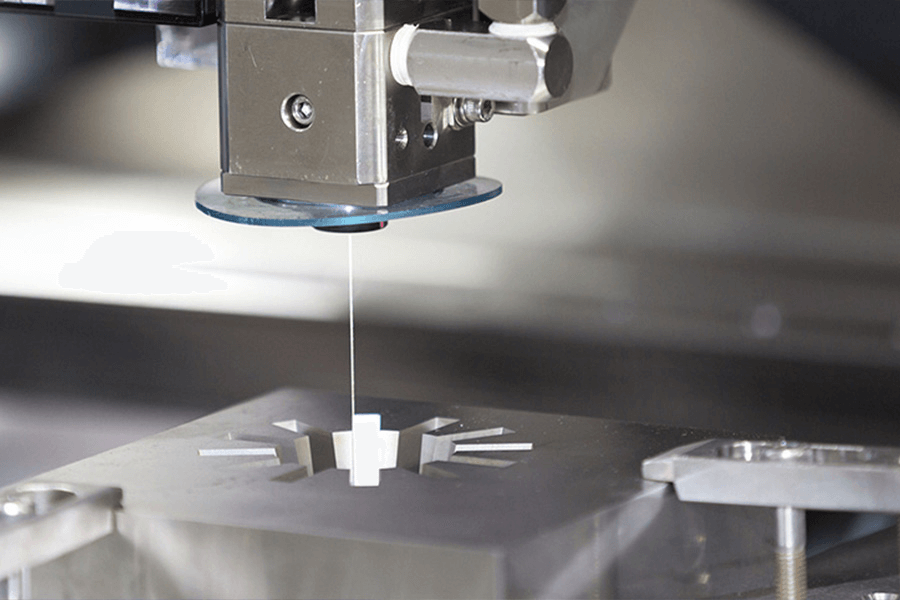

Sinker EDM Machining is a non-traditional machining process that utilizes electrical discharges to erode material from a workpiece. The process involves a specialized machine, commonly known as a “sinker EDM machine,” which creates a spark between an electrode and the workpiece. The spark generates intense heat, melting and vaporizing the material, resulting in the desired shape or cavity.

How Does Sinker EDM Machining Work?

- Electrode and Workpiece Setup: To begin the Sinker EDM Machining process, a precisely machined electrode, typically made of graphite or copper, is carefully aligned and lowered towards the workpiece. The workpiece, often made of conductive materials such as steel or titanium, is submerged in a dielectric fluid, usually deionized water.

- Spark Generation and Material Erosion: Once the electrode and workpiece are positioned, an electric current is applied, creating a series of rapid electrical discharges between the electrode and the workpiece. These discharges, also referred to as sparks, create a controlled erosion process. As the sparks occur, small particles of the workpiece are vaporized, leaving behind a cavity or shape that matches the electrode.

- Flushing and Debris Removal: During the machining process, the dielectric fluid acts as a coolant and insulator, preventing the spark from causing damage to the electrode or workpiece. Additionally, the dielectric fluid carries away the debris generated during the erosion process, ensuring a clean and precise machining operation.

Common Uses of Sinker EDM Machining

- Tool and Die Manufacturing: Sinker EDM Machining is widely employed in the production of intricate tool and die components. Its ability to create complex shapes and intricate details makes it invaluable for manufacturing molds, dies, punches, and other tooling components. The precise and repeatable nature of Sinker EDM Machining ensures the production of high-quality and dimensionally accurate parts.

- Aerospace Industry: The aerospace industry often relies on Sinker EDM Machining for manufacturing critical components such as turbine blades, fuel injectors, and engine parts. The process allows for the creation of intricate features that are crucial for optimal performance, durability, and efficiency. Sinker EDM’s ability to work with heat-resistant materials and maintain tight tolerances makes it a preferred choice in this sector.

- Medical Device Manufacturing: The medical field demands extreme precision and intricate designs in the production of surgical tools, orthopedic implants, and dental prosthetics. Sinker EDM Machining is well-suited to fulfill these requirements. It enables the creation of highly complex shapes and ensures the production of biocompatible materials with exceptional accuracy.

- Electronics Industry: The electronics industry heavily relies on Sinker EDM Machining for the production of components such as connectors, molds for plastic injection, and precision parts for microelectronic devices. Sinker EDM’s ability to machine conductive and non-conductive materials makes it an ideal choice for this sector, where miniaturization and intricate designs are crucial.

Why Choose “Iron Machine Tool” for Sinker EDM Machining?

When it comes to Sinker EDM Machining services, “Iron Machine Tool is a trusted and reputable provider that offers exceptional expertise and state-of-the-art equipment. Here are a few reasons why you should consider hiring “Iron Machine Tool” for your Sinker EDM Machining needs:

- Cutting-Edge Technology: “Iron Machine Tool” is equipped with the latest Sinker EDM machines that incorporate advanced features and cutting-edge technology. This ensures precise and efficient machining, allowing for complex designs and tight tolerances.

- Skilled Professionals: The team at “Iron Machine Tool” consists of highly skilled and experienced professionals who possess in-depth knowledge of Sinker EDM Machining. They have a keen eye for detail and are committed to delivering top-notch results.

- Customized Solutions: “Iron Machine Tool” understands that each project has unique requirements. They work closely with their clients to provide customized solutions tailored to their specific needs. Whether it’s prototyping, small-scale production, or large-scale manufacturing, they can accommodate a wide range of projects.

- Quality Assurance: Quality is of utmost importance at “Iron Machine Tool.” They have stringent quality control processes in place to ensure that every machined component meets the highest standards. By choosing their services, you can have confidence in the accuracy, precision, and durability of the final product.

- Timely Delivery: “Iron Machine Tool” values promptness and understands the significance of meeting project deadlines. They have a track record of delivering projects on time, ensuring that your production schedules are not compromised.

- Cost-Effective Solutions: While maintaining exceptional quality, “Iron Machine Tool” offers competitive pricing for their Sinker EDM Machining services. They strive to provide cost-effective solutions without compromising on the quality of the end product.