There are many ways to separate your ore from its waste rock. It all depends on what sort of ore you have and what sort of waste rock you have.

Not surprisingly, you have a wider range of options when your ore is valuable than when it’s not. But whether you’re separating gold-rich ore from low-grade ore, you’ve got to separate it somehow.

That’s where grinding mills come into the picture. Grinding mills are one of the most commonly used pieces of mining equipment.

But what are they? How do they work? Read on for a brief guide that’ll answer those questions and more.

What Are Grinding Mills?

Grinding mills are machines that handle bulk materials, ranging from wood, grains, metals, and more. They are typically used to process ore, coal, and glass.

Types of Grinding Mills

With milling projects, you need to use a different machine based on the material to grind. Common types available include the following:

Ball Mill

The term ball mill applies to the mill that stores the mixture in a cylindrical device. It uses balls to grind and blend the material.

Tube Mill

A tube mill is similar to a ball mill but with different proportions. They are long and use pebbles, balls, or slugs to grind material.

Rod Mill

Rod mills use iron rods to grind materials, as opposed to ball mills which use steel balls. The iron rods used in rod mills are much larger than the steel balls used in ball mills. This makes them more suited for larger materials.

Pebble Mill

Pebble mills are grinding mills that contain materials in their steel shells, and either use steel, ceramic, or porcelain balls as the grinding mechanism. Pebble mills are commonly used in cement, chemicals, copper, and other industries.

How Do Grinding Mills Work?

The grinding mill is powered by either a gas or electric motor. When the motor turns, it rotates an internal drive wheel, which in turn spins the grinding mill.

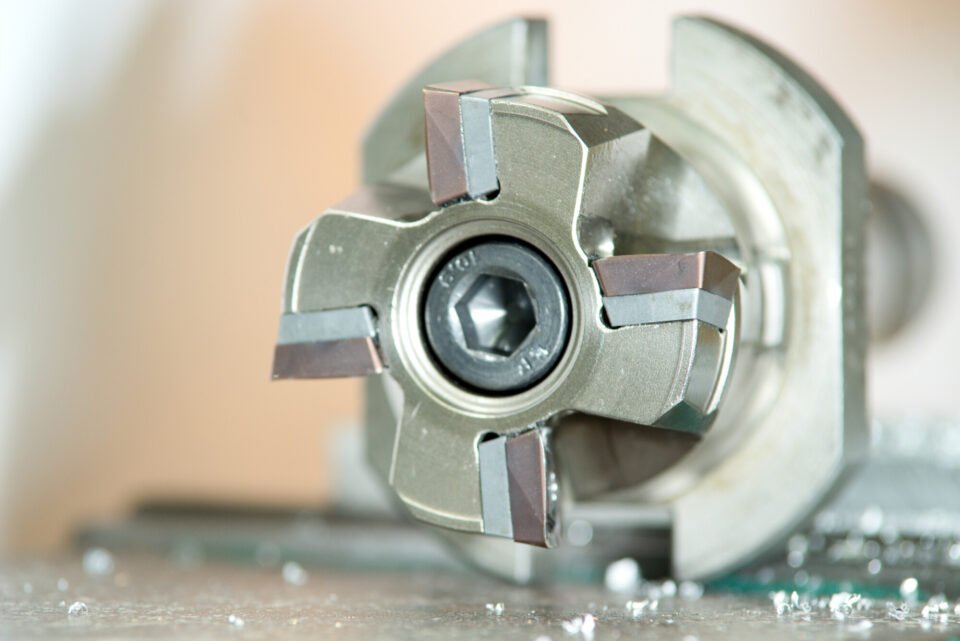

The grinding mill has several components, including a grinding chamber, inner and outer discs, support frames, and girth gears pinions. The girth gears are the most important component in the mill as they transmit power from the motor to the grinding chamber. The pinions are equally important as they give the girth gears power, allowing them to turn and rotate.

The Difference Between Grinding vs Milling

Grinding mills and milling machines both work by reducing the size of particles. Both have specific uses and can improve the quality of a product by providing the desired shape or finish.

However, grinding mills break down larger particles into smaller pieces. They are powerful enough to grind materials into granular or powder form.

Whereas milling machines are used to shape solid parts into intricate shapes. They can generate a higher quality of surface finishes than grinding mills can.

Utilize Grinding Mills

Grinding mills are essential equipment for businesses specializing in manufacturing and processing. Knowing key details about the design, power, and performance of grinding mills is necessary to ensure optimal efficiency.

From materials it can grind to its power output, understanding grinding mills is essential for anyone working in the industry. Contact a reliable supplier today and get the best grinding mills available!

Was this article helpful? If you want to learn more guides like this, check out our blog!